Trucks & Equipment

THERMOPLASTIC

Productive

Offered in a wide range of models, MRL Equipment Company’s robust thermoplastic striping equipment has a reputation for reliability and high productivity.

Products

Videos

ThermoPro™ Thermoplastic Striper in action

EN ESPAÑOL MRL THERMOPRO™ THERMOPLASTIC STRIPER

MRL’s truck-mounted line of ThermoPro™ Thermoplastic Stripers provides superior material pre-melting capability to assure faster start-ups and more productive applications. The ThermoPro™ series provides air atomized spray application, ribbon extrusion application, and screed extrusion flat or profile application.

The ThermoPro™ series is available in ThermoPro™ 4000, ThermoPro™ 8000, ThermoPro™ 12000, ThermoPro™ 16000, and ThermoPro™ 24000.

Features

- High-capacity hydraulic system enables simultaneous yellow and white thermoplastic application.

- Material recirculation system for precise pressure control and enhanced pump life.

- Choice of propane or diesel fuel-fired heating system.

- Safe, automatic, electronic pre-melter ignition system.

- Auxiliary material inlet to enable refilling pre-melters from a different source.

- Material storage area with removable side railings.

- Vacuum bead loading system.

- Combination Imperial/Metric stripe control system.

- Voice-activated wired or wireless intercom system.

- Color video guidance system with flatscreen monitor and video crosshair generator.

- Safety and warning light package.

- Optional hydrostatic chassis propulsion system to precisely control material application speeds.

- Optional laser guidance system.

- Optional touchscreen control system with material usage monitoring and data logging capabilities.

- Optional automated thermoplastic bulk material melter loading system.

- Optional pallet-lifting jacks or conveyor loading systems are available.

- Extensive, industry-leading service and parts support from MRL’s specialized staff.

- Comprehensive parts and service manual.

Videos

LEARN MORE ABOUT THE DETAILPRO™ THERMOPLASTIC SUPPLY TRUCK

Increase productivity with an MRL DetailPro™ Thermoplastic Supply Truck and enhance your total melting capacity. Available in numerous configurations and material capacities. Add options such as transfer pumps, conveyor belt melter loading, transfer hose booms, lift gates, and more to get the most out of this workhorse.

The DetailPro™ series is available in DetailPro™ 3000, DetailPro™ 4000, DetailPro™ 6000, DetailPro™ 8000, DetailPro 12000, and DetailPro™ 16000.

Features

- Mounted with pre-melting kettles in varying capacity options.

- Bed storage and D-ring tie-downs for handliner or Mini Mac® Thermoplastic Striper.

- Optional arrowboard.

- Optional custom stencil rack.

- Extensive, industry-leading service and parts support from MRL’s specialized staff.

- Comprehensive parts and service manual.

Videos

LEARN MORE ABOUT THE DETAILPRO™ THERMOPLASTIC SUPPLY TRAILER

The MRL DetailPro™ Supply Trailer is configurable with pre-melting kettles, material deck, and space for hauling Thermoplastic Handliners or Mini Mac® 400 Thermoplastic Stripers.

The DetailPro™ Trailer series is available in DetailPro™ 3000 Trailer, DetailPro™ 4000 Trailer, DetailPro™ 6000 Trailer, and DetailPro™ 8000 Trailer.

Features

- Thermoplastic pre-melting kettles in varying capacities.

- Bed storage and D-ring tie-downs.

- Optional safety lights and arrowboard.

- Optional liftgates.

- Extensive, industry-leading service and parts support from MRL’s specialized staff.

- Comprehensive parts and service manual.

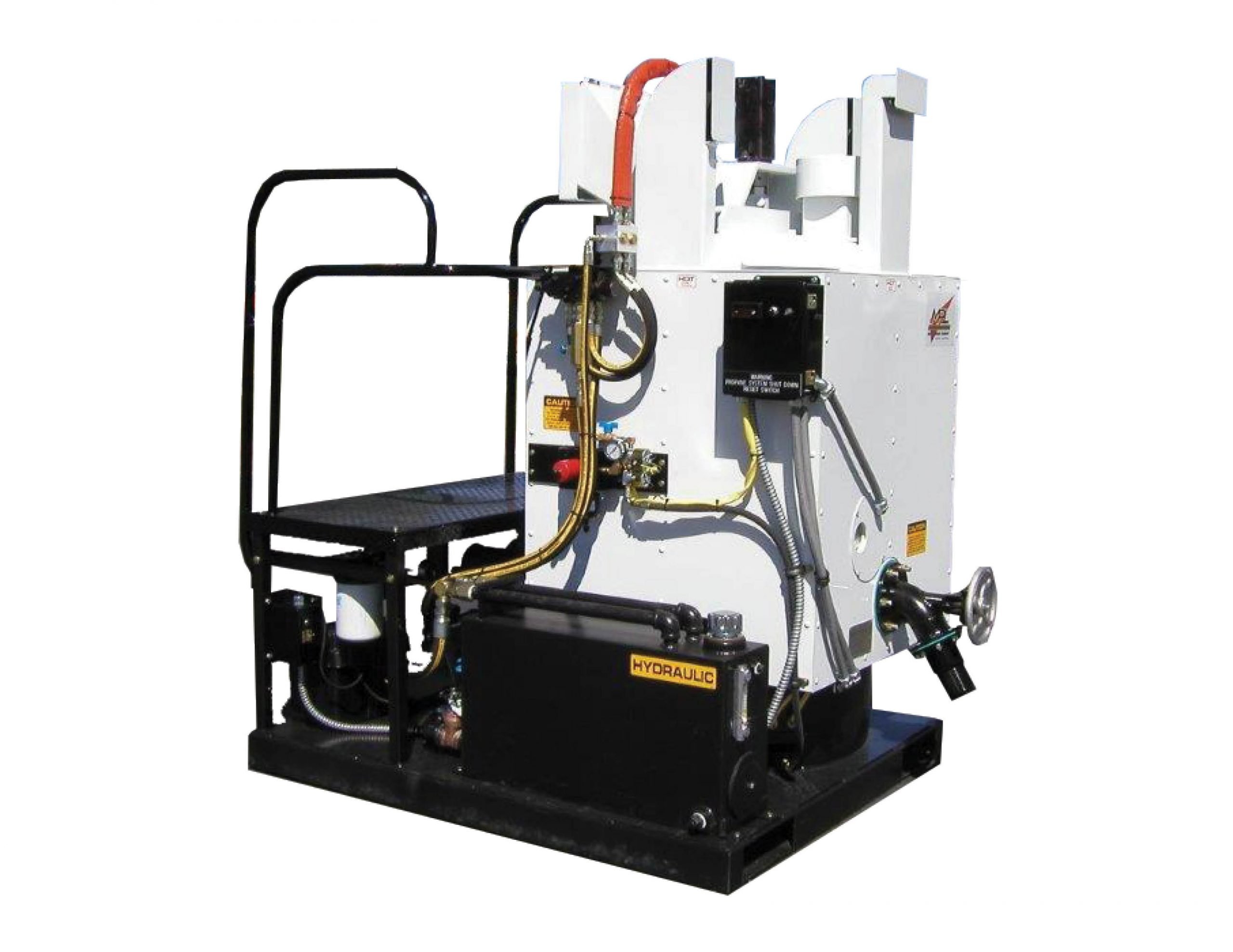

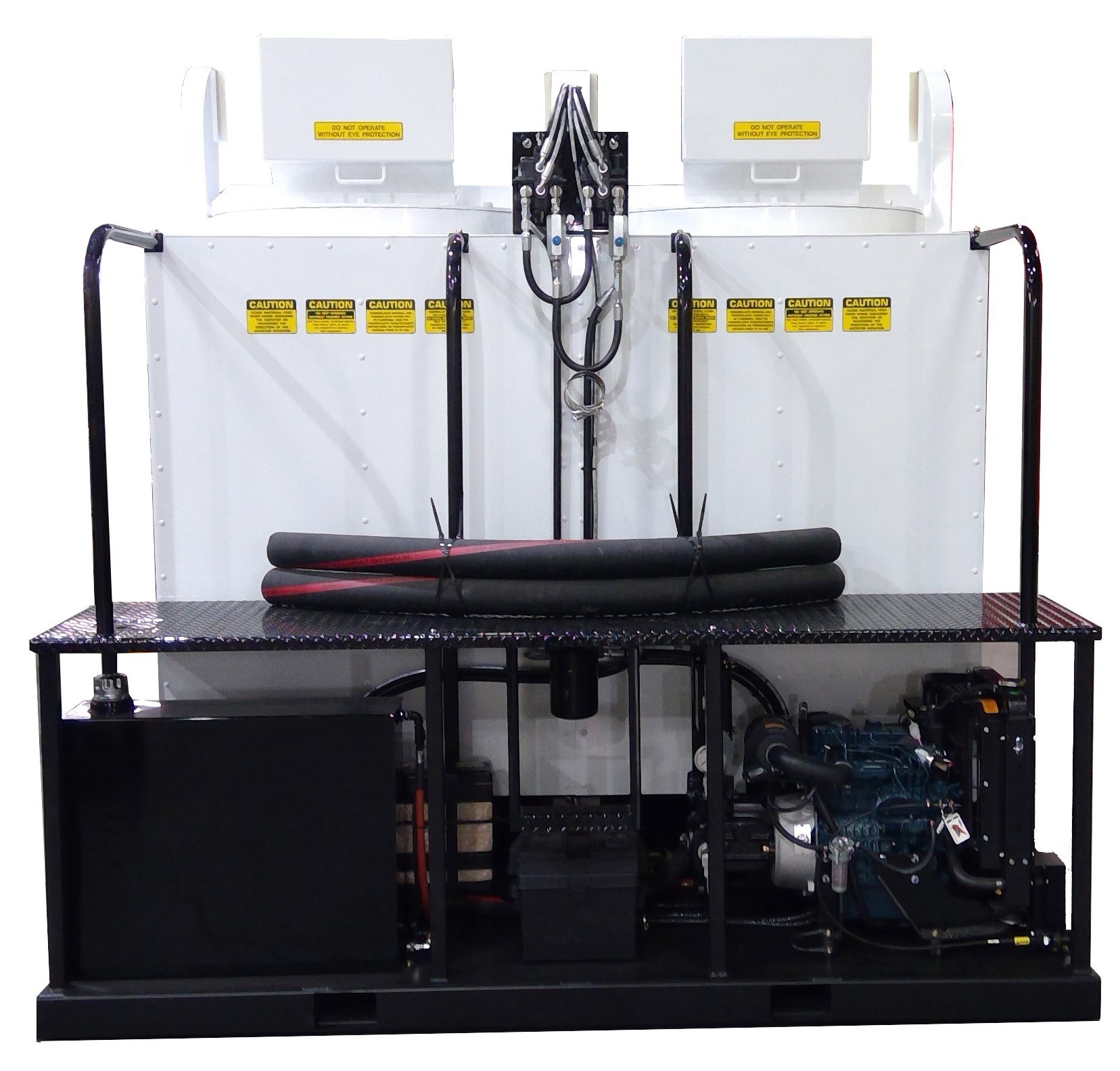

MRL’s ThermoPro™ Pre-Melting Kettles offer superior production capabilities in a self-contained, safe, durable, skid-mounted, air-jacketed vertical design.

Available in single kettle or dual kettle sets in 1000 lb/454 kg, 1500 lb/680 kg, 2000 lb/907 kg, 3000 lb/1360 kg, 4000 lb/1814 kg, 6000 lb/2721 kg, 8000 lb/3629 kg, 12,000 lb/5443 kg, and 16,000 lb/7257 kg capacities.

Features

- High output propane or diesel-fired kettle burners.

- Thermostatically controlled, automatic electronic ignition system.

- Hydraulically driven agitation system.

- Auger-enhanced agitator shaft designed to thoroughly mix the material and minimize glass bead settlement.

- Integral hydraulic power plant or remote-mounted hydraulic power plant options.

- Extensive, industry-leading service and parts support from MRL’s specialized staff.

- Comprehensive parts and service manual.

Videos

MINI MAC® THERMOPLASTIC STRIPER IN ACTION

En Español MRL Mini Mac® Thermoplastic Striper

The MRL Mini Mac® Thermoplastic Striper offers excellent versatility in a compact, productive design that enables the quick application of detail markings.

MRL Mini Mac® Thermoplastic Striper is available in 400 lb (181 kg) capacity, offering ribbon extrusion applications.

Features

- Durable material pump integral to the oil-jacketed material tank.

- Right-side application standard; optional left-side model available.

- Single- or double-drop glass bead application system available.

- LED work lights to illuminate the work area.

- Electronic Skip-Line timing system.

- Laser line guidance system available.

- Extensive, industry-leading service and parts support from MRL’s specialized staff.

- Comprehensive parts and service manual.