MRL Equipment’s selection of in-stock equipment is a great way to put machinery in the field quickly so you can focus on productivity.

Check out our current selection of new, MRL Certified Pre-Owned, and used water-borne paint, thermoplastic, and plural component epoxy/polyurea application units in numerous sizes. Line removal units -- some with grooving capabilities -- are also available.

Please call our office at 1.877.788.2907 or use our Contact Form to discuss the details of your equipment needs.

New In Stock

MRL Equipment’s selection of in-stock equipment is a great way to put machinery in the field quickly so you can focus on productivity.

Contact

Kent Klein - kklein@markritelines.com

David Kautz - dkautz@markritelines.com

Brian Pardoe - bpardoe@markritelines.com

Justin Schmidt - jschmidt@markritelines.com

406.869.9900

Features

MRL RumblePro Machine

- Peterbilt 537 Chassis

https://www.markritelines.com/equipment/rumble-pro

Contact

Kent Klein - kklein@markritelines.com

Brian Pardoe - Bpardoe@markritelines.com

David Kautz - dkautz@markritelines.com

Justin Schmidt - jschmidt@markritelines.com

1.877.788.2907

Features

The MRL Detail Trailer w/RH Mini Mac 400

- 2K Pre-Melter Kettles

- RH Mini Mac 400

- 18" Gun

- Laser

- Non pressurized Double Drop bead system

- Spare parts kit

- Easy-load trailer with room for material

- Extensive, industry-leading service and parts support from MRL’s experienced staff.

- Comprehensive parts and service manual.

Contact

Kent Klein - kklein@markritelines.com

Brian Pardoe - Bpardoe@markritelines.com

David Kautz - dkautz@markritelines.com

Justin Schmidt - jschmidt@markritelines.com

1.877.788.2907

Features

The MRL Mini Grinder offers excellent versatility in limited work zones. This self-propelled ride-on unit is designed to remove pavement markings, groove for inlaid markings, and slot cut for raised pavement marker installation. Agile, compact design enables efficient production in congested work areas.

- 8″/20.3 cm diameter cutting heads with the ability to cut up to 13″/33 cm wide; accepts PCDs, diamond blades, or carbide cutter drums.

- 1500 CFM vacuum system/42.5 CMM vacuum system.

- 2.67 ft3 of debris storage/0.08 m3 of debris storage.

- Easy-load trailer with debris storage bin is available.

- Extensive, industry-leading service and parts support from MRL’s experienced staff.

- Comprehensive parts and service manual.

In Stock

Contact

Kent Klein - kklein@markritelines.com

Brian Pardoe - Bpardoe@markritelines.com

David Kautz - dkautz@markritelines.com

Justin Schmidt - jschmidt@markritelines.com

406.869.9900

Features

The MRL Mini Mac® 400 Thermoplastic Striper offers excellent versatility in a compact, productive design that quickly applies detail markings.

- 400 lb/181 kg capacity material tank.

- Powered by a 25-hp LP-fueled engine.

- 100 lb/45 kg double-drop bead application system.

- Durable material pump integral to the oil-jacketed material tank.

- Easily adjustable thermoplastic extrusion dies and spray guns enable quick stripe width changes.

- Right-side application.

- LED work lights to illuminate the work area.

- Laser line guidance enables quick machine alignment.

- Simple operator controls.

- Extensive, industry-leading service and parts support from MRL’s experienced staff.

- Comprehensive parts and service manual.

In Stock

Contact

Kent Klein - kklein@markritelines.com

Brian Pardoe - Bpardoe@markritelines.com

David Kautz - dkautz@markritelines.com

406.869.9900

Features

MRL’s ThermoPro™ Pre-Melting Kettles offer superior production capabilities in a self-contained, safe, durable, skid-mounted, air-jacketed vertical design.

- Currently have 1K, 1.5K, and 2K sets that are completing production

Contact

MRL Parts at parts@markritelines.com

406.869.9900

Features

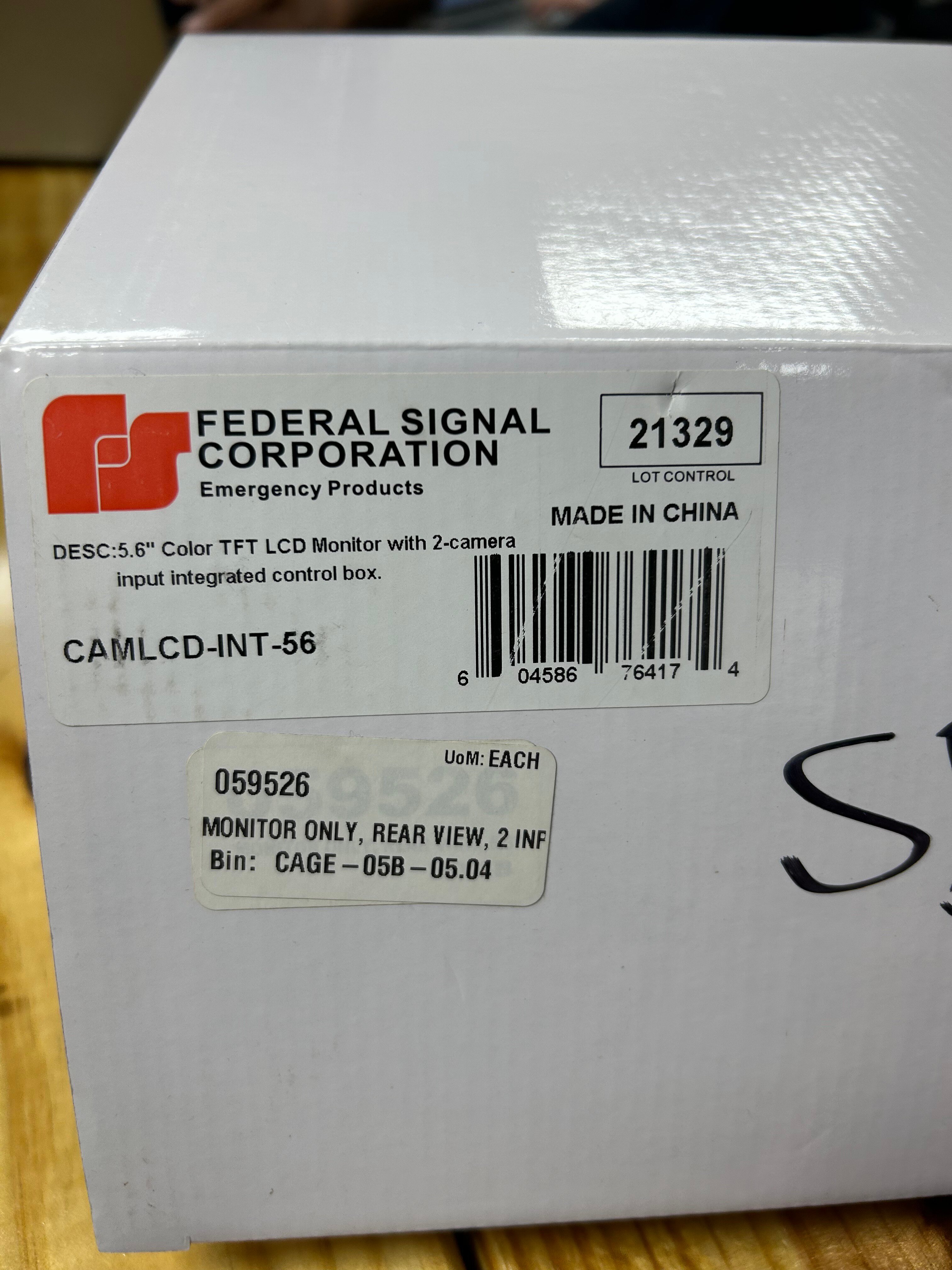

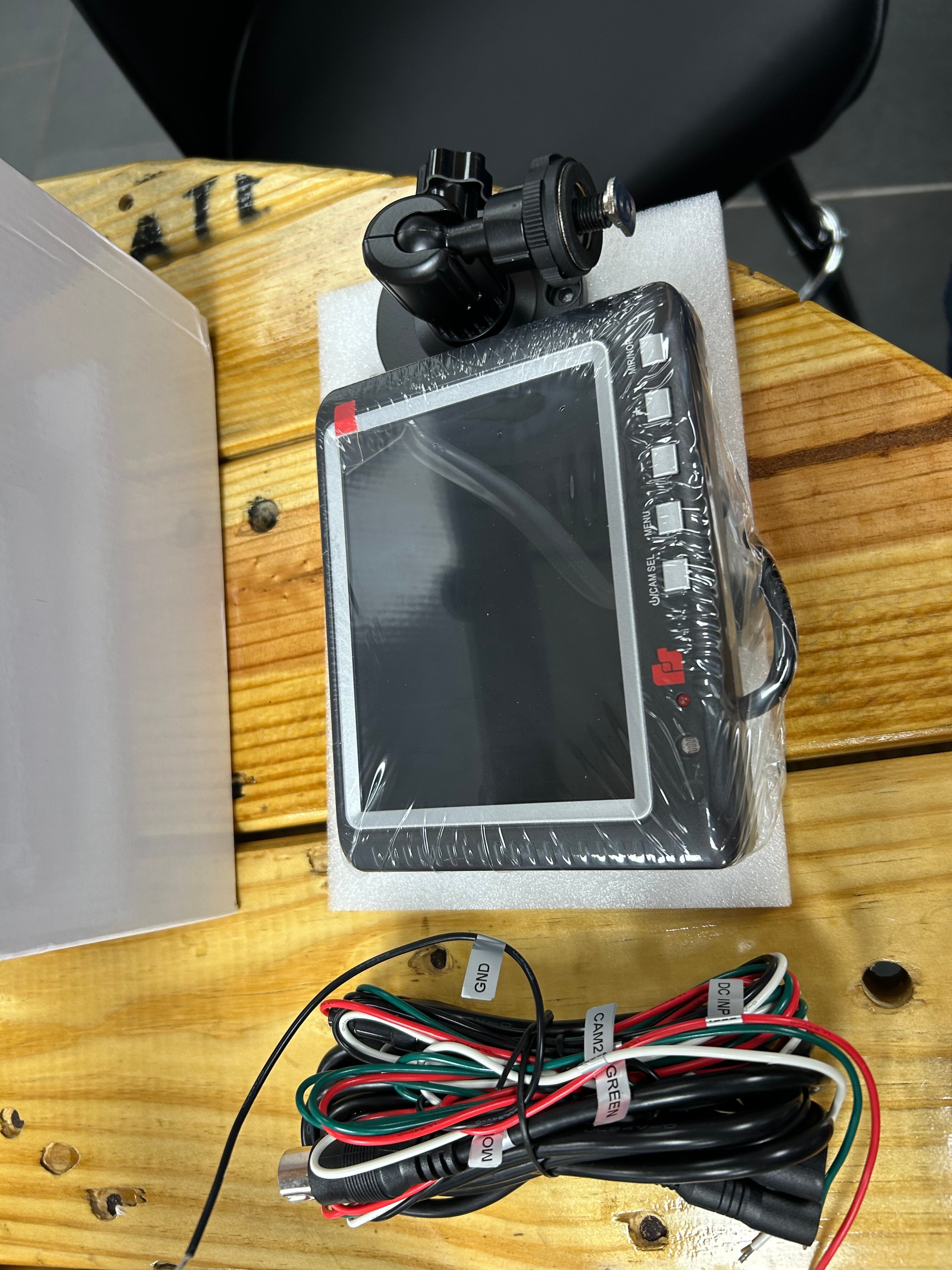

FS 5.6" Color TFT LCD Monitor with 2-camera input integrated control box - Monitor Only, Rear View

Use to sell at $378

While supplies last $100.

A brand new MRL Thermo truck will be available around May 15th. This truck is for sale by Owner.

4-8000 Thermoplastic Truck

Low-Hour Customer Supplied Paletech 260 CFM Compressor

Dueal Diesel Burners

Single Drop Bead system

C/L Carriage - 2 Yellow Guns, 1 dedicated White

E/L - 1 white gun

MRL Roper pumps

3000Lb ASME Cert Bead Tank

Canadian Compliant chassis

Contact

Pierre Brousseau - Total Traffic - 416-407-7711

pierre@totaltrafficservices.com

Unused 1K Pre-Melter Kettle

20 HP Kohler Propane fueled hydraulic power plant

hydraulic pump

hydraulic reservoir

battery and battery box mounted under the feed step platform.

Please contact

Donny Leader | Fleet Superintendent

City of Hillsboro | Public Works Department

503-681-6428 (office) | 503-997-0820 (cell)

Used Equipment

MRL has a variety of used equipment that we own that we will place here on the site and the units are sold "as is". We will also assist our customers will selling their used equipment. That equipment sale is between the two parties and not MRL. We will only list equipment for our customers that are purchasing from us.

Contact

David Gagliano - KSI - 303-688-9516

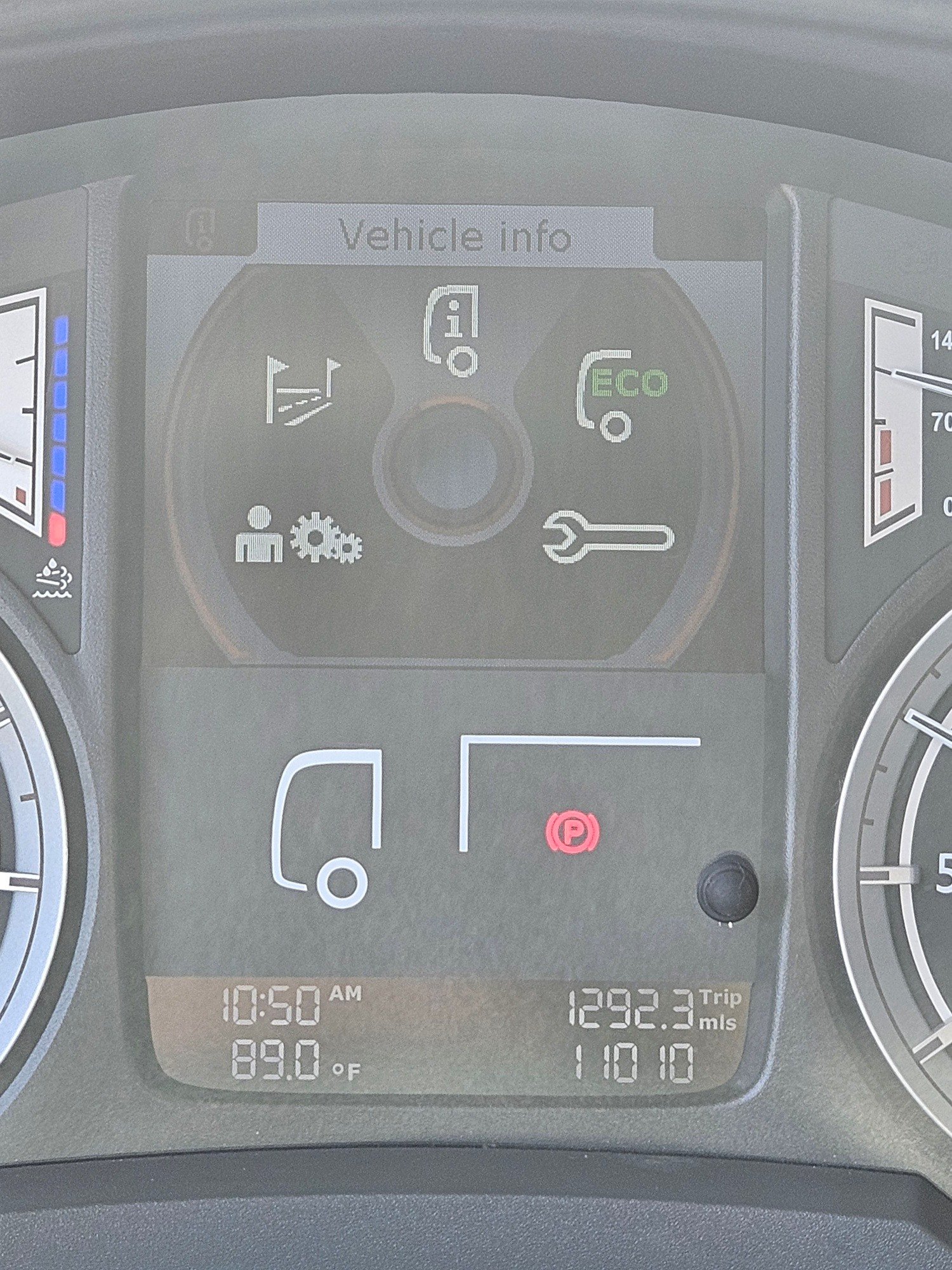

Features

- Miles, 26,208

- Chassis, 2021 Peterbilt 520

- Aux Eng, John Deere Tier4 Genset

- Headsets, 3 bluetooth liberator MAX

- Spray guns, Fusion Air Purge Plural Componet

- Left, 2 yellow, 1 white

- Right, 1 white

- Tanks material,

- Yellow, 200g

- Catalyst, 200g

- White, 200g

- Black, 60g

- Beads,

- Main tanks – 5,000lbs each

- Black beads.

- Pumps, Material Pump: Big Ace

- Black pump, Graco

- Load pumps, Hydraulic Graco Rotary ball pump

- Compressor, Rotorcomp

- Pointersytem, Laserline lazer pointer

- Data logging, Skipline

- Arrowboard, Wanco VMA

- Generator, MagnaPlus from Marathon Electric

Contact

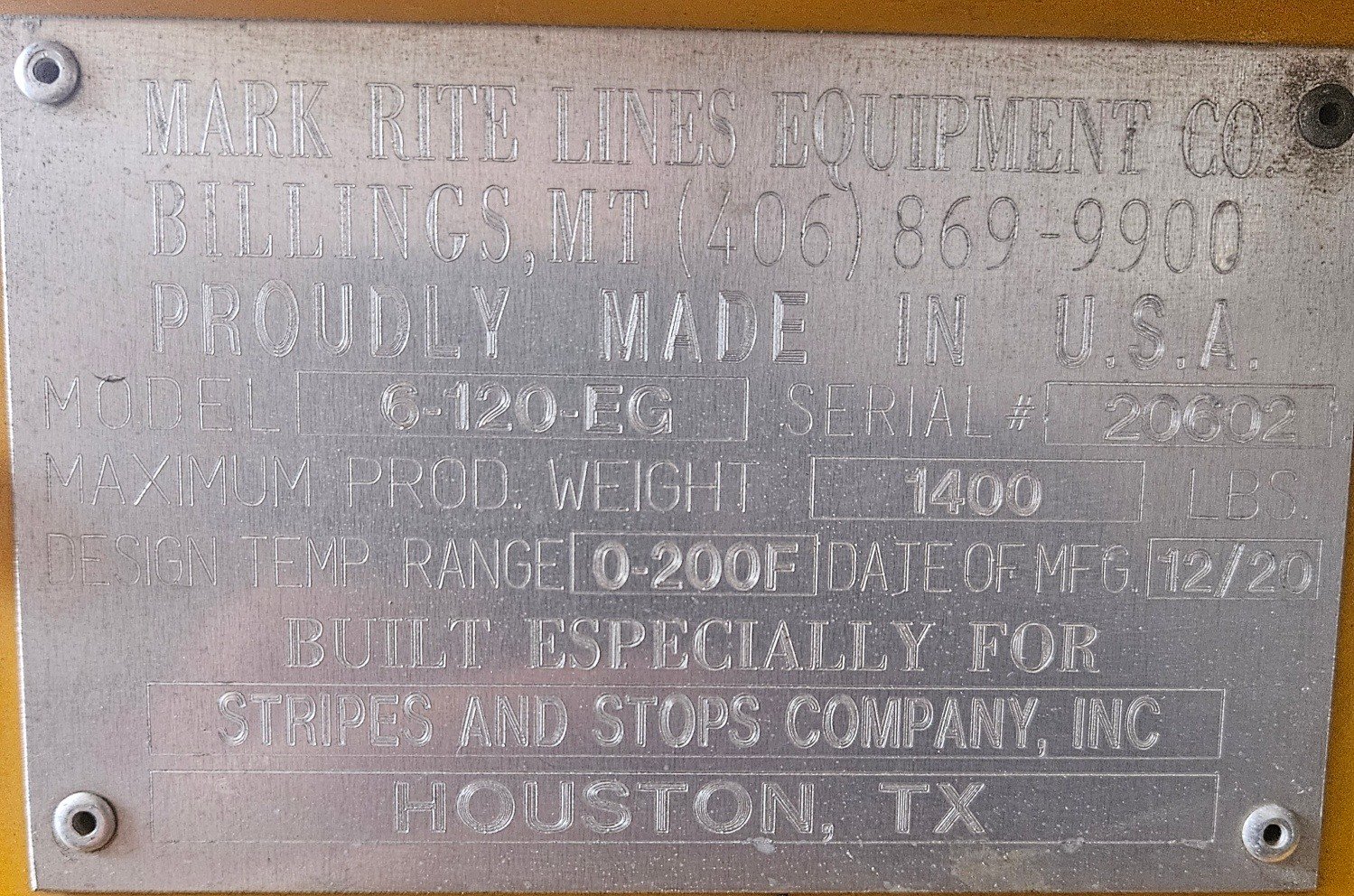

Stripes & Stops - Steve McKinley - 713-882-1651

Features

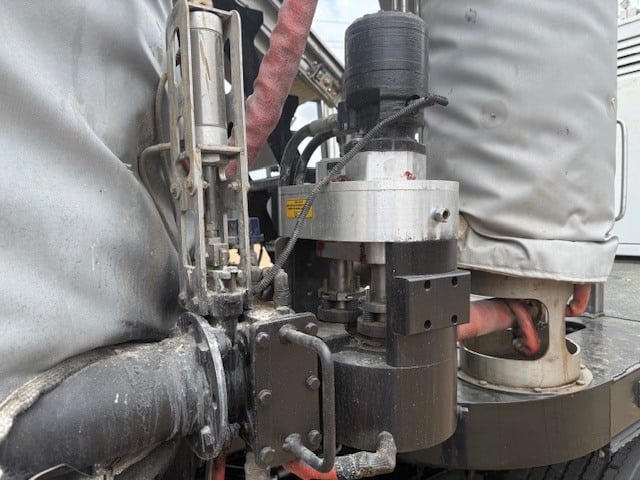

Epoxy Marker truck

26K GVW Non-CDL truck

60 gal tanks

13 CFM Air Compressor

PTO Hydraulic System

Epic Solutions Timing & Control System

2 Graco 2400 pump assembly

MRL Safety strobe and light package

Plural component technologies hand gun assembly

Custom tailboard for operator to hold markers