A 400 lb (182 kg) oil-jacketed, non-pressurized thermoplastic tank integrates a high-performance material pump with electronically controlled pump RPM and a digital RPM gauge. The thermostatically controlled LPG heat-transfer-oil system provides reliable temperature management through an oil circulation pump and digital controls.

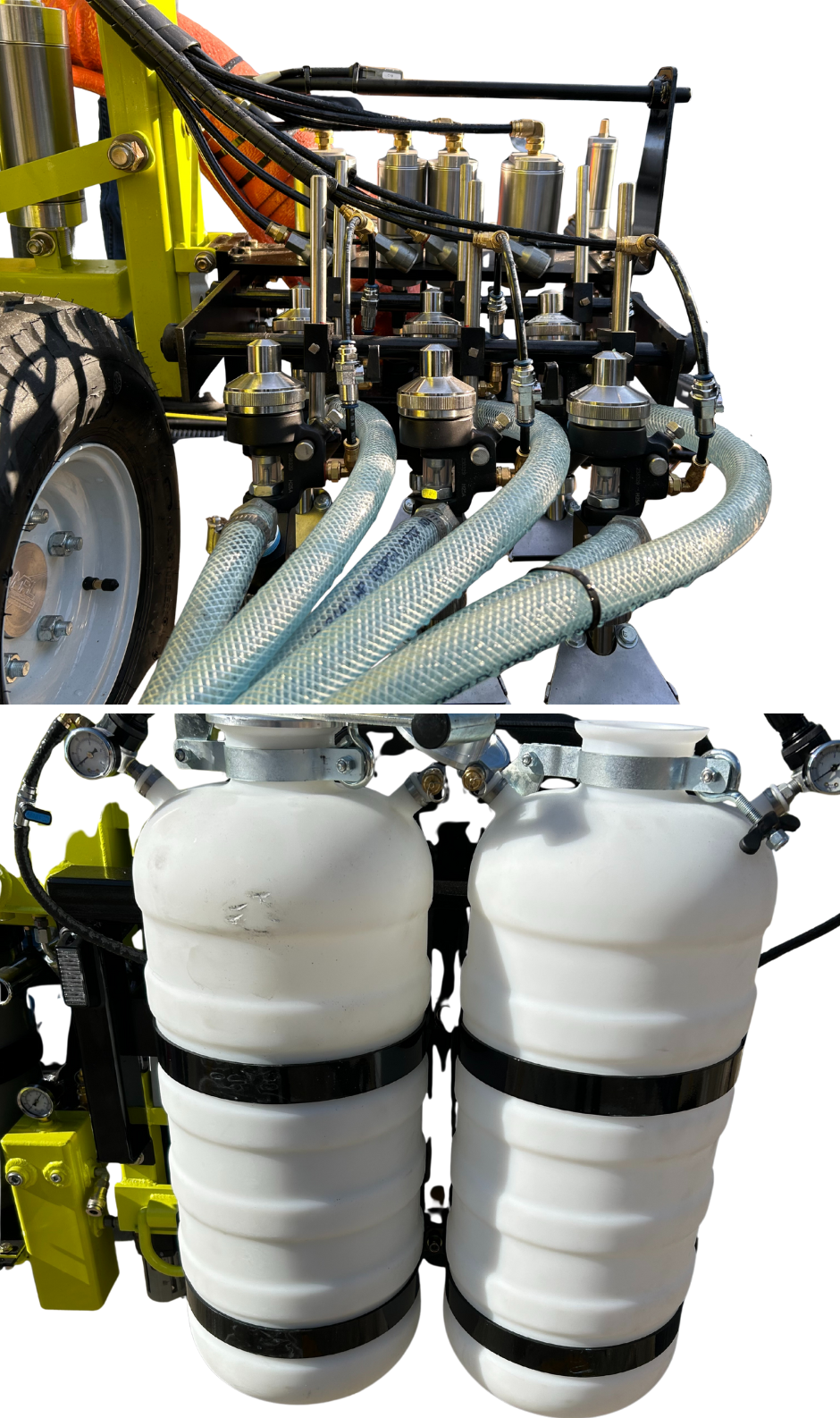

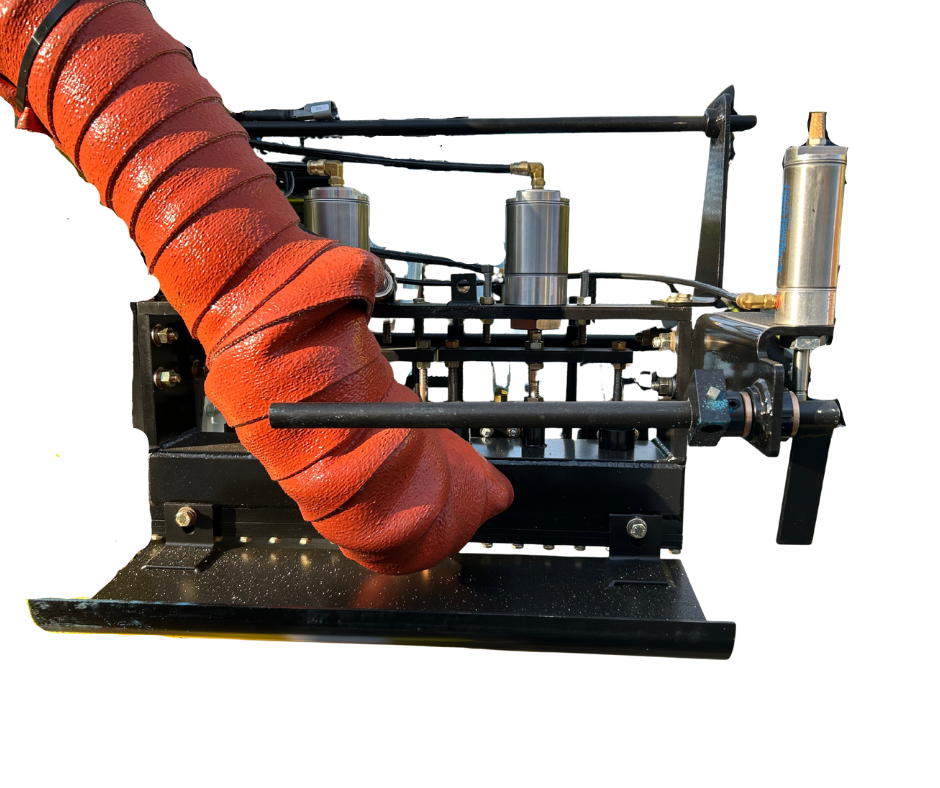

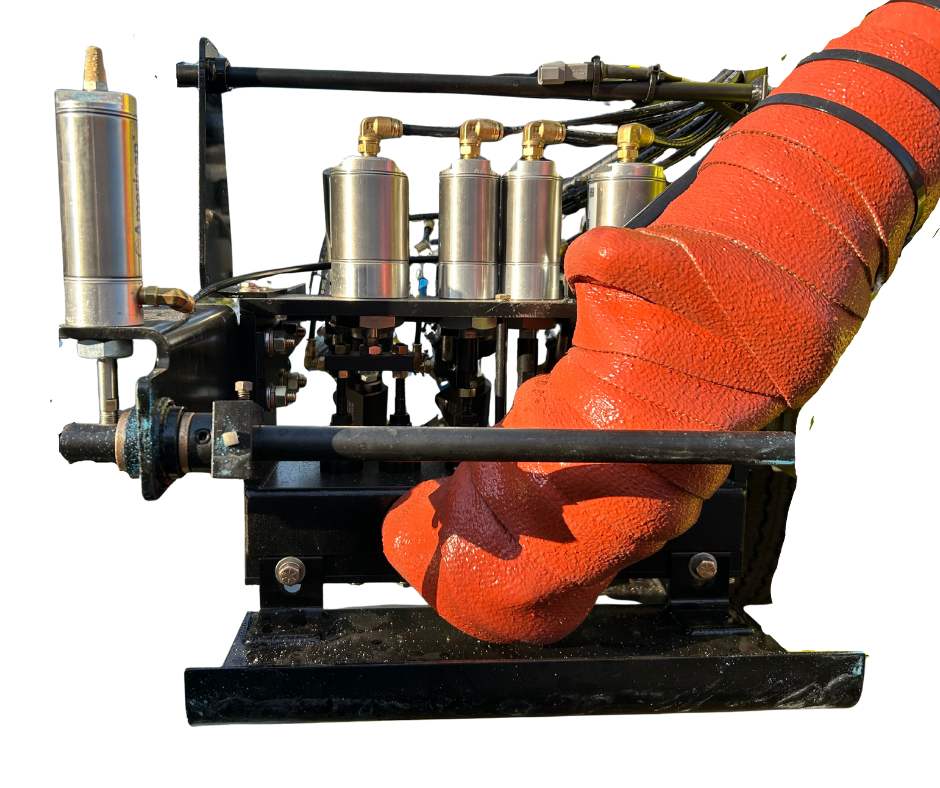

Adjustable application slides accommodate widths from 4" to 13" (10–33 cm). The ribbon-extrusion gun is equipped with an air-lift mechanism and transport-locking pin. A single-drop glass bead system includes a 100 lb (45 kg) bead hopper and three bead guns, each with adjustable air injection.

An 8 cfm, 110 psi air compressor supports the bead system, air unloader, moisture separator, operational solenoids, ribbon gun lift, and thermoplastic “blow-down” function. The electrical control console includes electronic burner controls, gun on/off switches, gun test switches, pilot light, and a remote E-Stop engine shutdown feature.

The operator benefits from an adjustable alignment pointer with air-actuated lift, with an optional laser pointer upgrade. The comprehensive safety lighting package includes three LED night-work lights—illuminating the tank fill port, forward work area, and gun carriage—along with two Whelen LED amber strobes positioned at the rear and on the elevated mast.

A secure travel latch is built into the front of the machine, with an optional steel trailer-bed latch available. Standard finish is Lime Squeeze Green with a silver material tank; optional colors are available for an additional charge. The unit is backed by a one-year warranty on all MRL-fabricated parts.

The integrated skip timing system features a color display, programmable skip cycles, footage counters, bead lead/lag adjustments, and storage for up to three profiles.

- Self-contained "Hi-torque" hydraulic agitator drive motor(s) with directional control valve(s).

- "Auger" enhanced steel agitator shaft assembly.

- Steel abrasion resistant agitators shaft assembly with replaceable hardened “stub” shafts and replaceable hardened bushings.

- High-temperature ceramic insulation installed on combustion chamber floor

- Thermostatically controlled, automatic electronic ignition system with fuel safety shutdown feature

- Anti-splash material feed chutes with safety "flash" deflectors.

- Stainless steel-lined burner compartment(s) with floating stainless steel deflector plates to enhance burner compartment durability.

- 2” Insulation jacket between the material tank and exterior panels for superior heat retention and operator safety.

- Removable steel feed step assembly with side handrails

- Fork-lift channels installed in the melter base.

- MRL one-year warranty on MRL fabricated parts.

Configuration Details:

- Burners per Kettle

- Single burners only on stand alone units

- Dual burner option on Pre-Melter Quad units

- Feed Step Height

- 24” for all propane power plants

- 32” for all diesel power plants

The DetailPro Trailer is the ideal solution for contractors looking to expand into more roadwork, intersections, and small-scale projects, as well as for municipalities and DOTs seeking to bring thermoplastic road marking in-house, eliminating the wait for outside contractors.

Designed with flexibility in mind, the DetailPro Trailer can be tailored to meet your specific operational needs. Whether you're handling small jobs and only need a single kettle or require additional capacity for larger projects, we offer configurations that scale with your work.

Freight is F.O.B. Billings, MT

All units include one (1) day of technical start-up training conducted at the MRL facility in Billings, MT.

- Configuration

- Bead Systems

- Gun Systems

- Other Options

- Summary/Quote

- Model

- Size

- Engine Size

- Fuel Tanks

- Engine Mount

- Outlet Valve(s)

- Material Load Hose

- Interconnect Valves

- Colors

- Summary/Quote

- Trailer

- Melter

- Arrow Board

- Summary/Quote

- Model

- Options

- Summary/Quote

Custom colors include:

White

Safety Yellow

Traffic Orange

- Paint code: (customer provides)

- Paint Scheme: (customer provides)

.jpg)

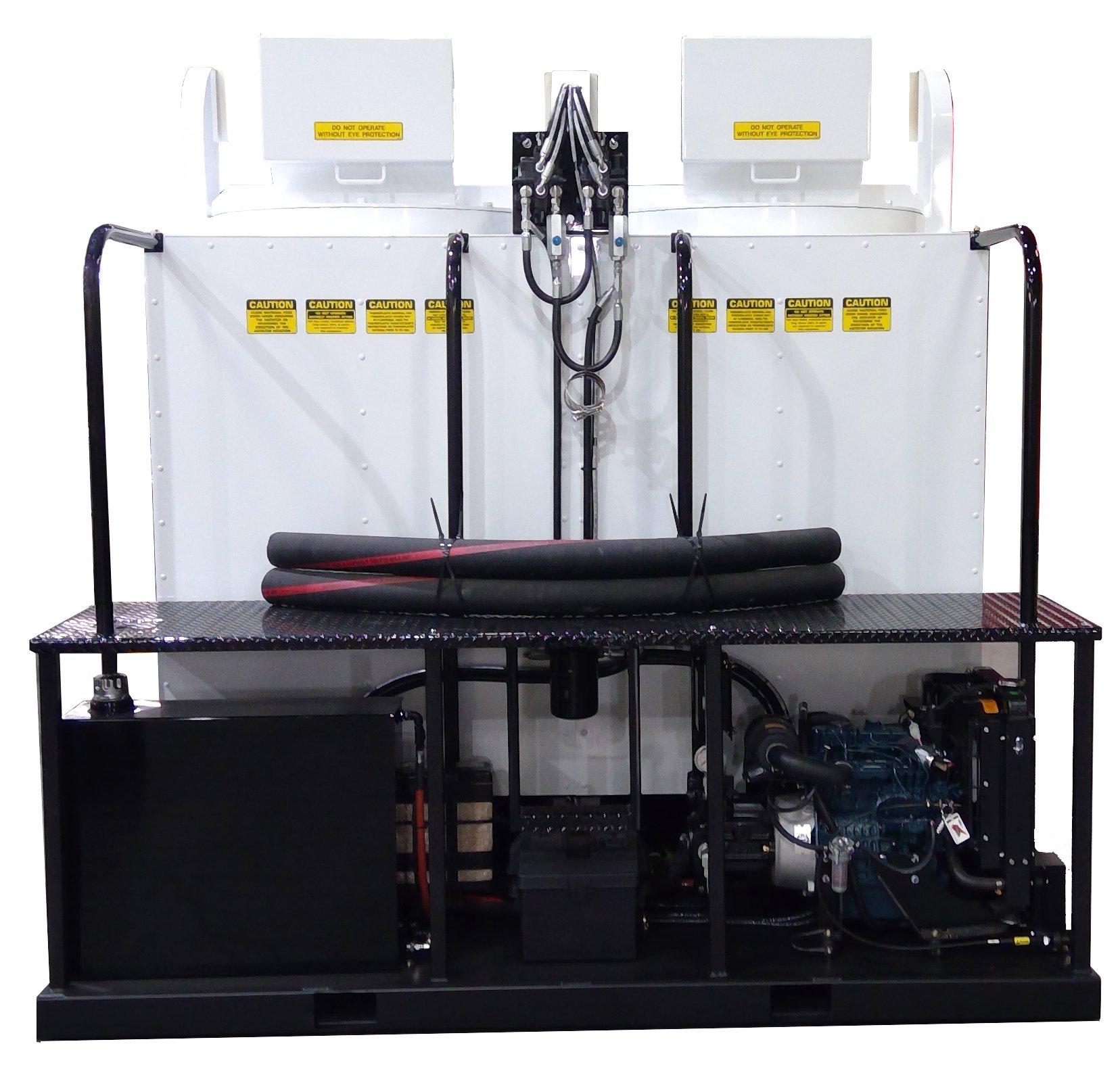

One (1) 1.5k Set capacity Diesel Fired air-jacketed, vertical design thermoplastic pre-melting kettle set (3,000 lbs. total capacity), with a 21 HP Kubota 3-cylinder diesel fueled engine to power the hydraulic requirements, with battery and battery case and hydraulic tank, 16 gallon mounted under the feed step platform. (Available to select for the 18ft and 14ft)

4ft x 8ft 25 light LED WANCO multifunction arrow board mounted to melter. Controller mounted near melter.

(only available on melter set configurations)

4ft x 8ft 25-light LED WANCO multifunction arrow board mounted to a mounting bracket at the rear of the trailer. Controller mounted near melter. (Only available for single melter configurations)

Bridger PaintPro 1-100-AA Tote

Features

- Isuzu Chassis

- 1200lb Bead tank

- (2) Totes

- Boss Air Compressor

- 15-Gallon hydraulic tank with dual heat exchanger

- Pointer bar

- (2) MRL Toolboxes

- Aluminum Canopy

- Safety and warning light package

- MRL backup camera system

- 6 GPM Titan pumps

- Aluminum tailboard 12x72

- Rear-mounted arrowboard

Bridger PaintPro 1-240-ALS Tote

Features

- Isuzu Chassis

- 1200lb Bead tank

- (2) Totes

- Boss Air Compressor

- 15-Gallon hydraulic tank with dual heat exchanger

- Pointer bar

- (2) MRL Toolboxes

- Aluminum Canopy

- Safety and warning light package

- MRL backup camera system

- 6 GPM Titan pumps

- Aluminum tailboard 12x72

- Rear-mounted arrowboard

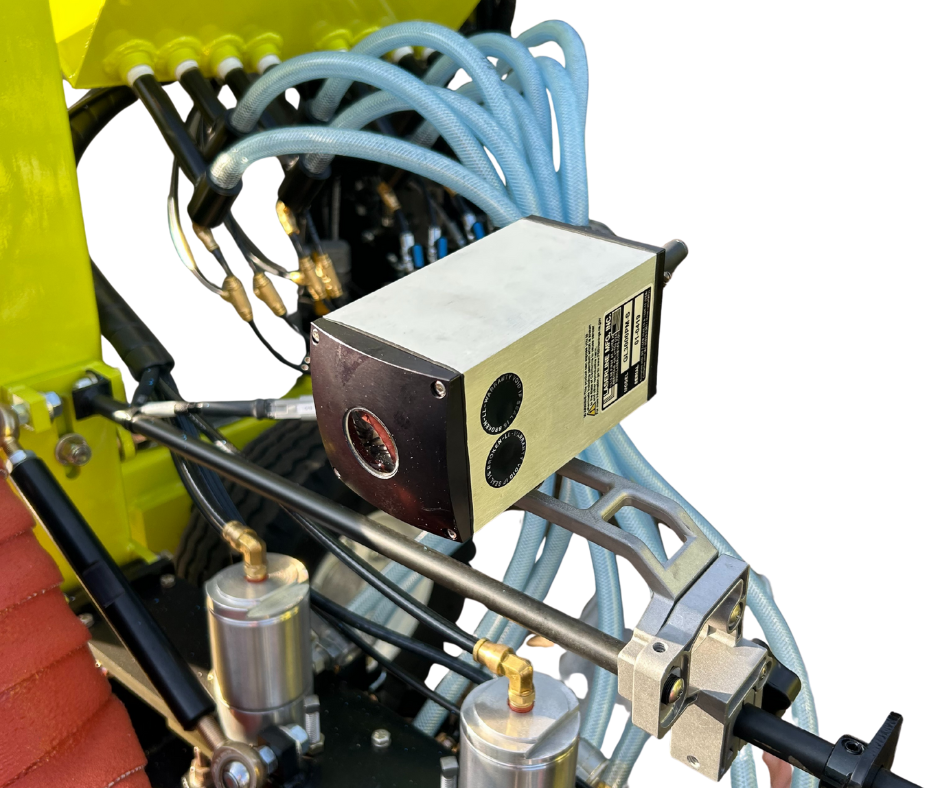

Two (2) HD camera color video guidance system. System includes:

- LCD flat screen color monitor w/suction mount and padded storage.

- A video crosshair generator w/controller.

- Two (2) color cameras w/auto iris lenses mounted inside MRL weather-resistant self-leveling housings.

- Two (2) electrically actuated camera mounting brackets under striper bed. One (1) edge line and one (1) centerline.

- Cab mounted, two position image selector switch.